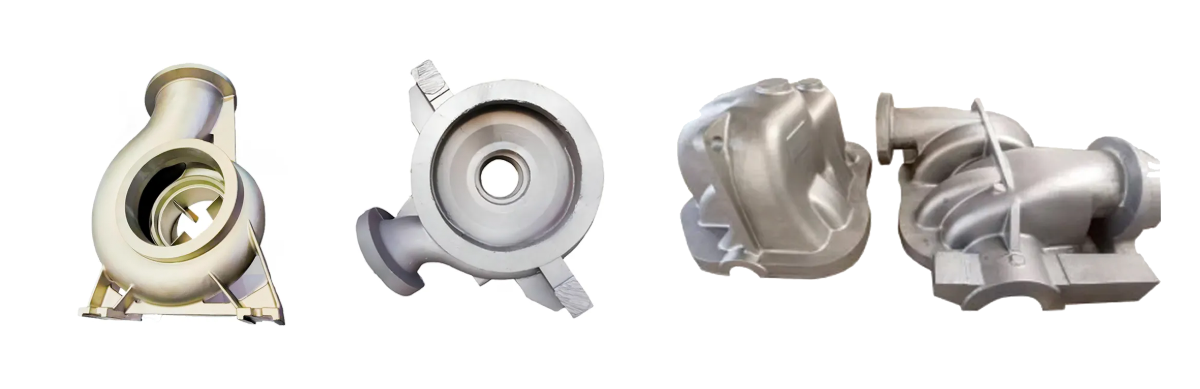

Pump housing molds play a crucial role in the manufacturing industry, primarily producing the casings needed by factories through metal forming processes (die casting or casting).

The production of chemical pump casings using pump housing molds typically involves the following steps:

1. Design Phase: Based on the specifications and requirements of the chemical pump casing, a detailed 3D design is performed. This design process needs to consider details such as the dimensions, shape, material, inner and outer contours of the Chemical pump casing, wall thickness, reinforcing ribs, etc., as well as the selection of mold steel, cooling system, demolding method, and the mold's runner system (i.e., the channel system used in injection molding, casting, etc.).

2. Mold Manufacturing: Mold manufacturing typically involves two main parts: the moving mold and the fixed mold. For stamping dies, the moving mold contains the movable parts that enable separation and deformation, while the fixed mold is a relatively fixed half-mold.

The mold may involve multiple steps, meaning it needs to be able to complete multiple consecutive processes, gradually shaping a flat sheet of metal into a complex chemical pump casing structure.

Mold manufacturing typically utilizes high-strength steel or other wear-resistant materials to withstand the high temperatures and pressures of the production process. Molds are usually manufactured using precision machining techniques (such as CNC machining) to ensure accuracy.

3. Material Selection: Choose appropriate materials based on the intended use and requirements of the pump casing. Commonly used materials include cast iron, stainless steel, and aluminum alloys. Material selection directly affects the strength, corrosion resistance, and wear resistance of the pump casing.

For example, a chemical pump casing should possess the following characteristics:

(1) Corrosion resistance; (2) High and low temperature resistance; (3) Wear and erosion resistance; (4) Reliable operation; (5) No or minimal leakage; (6) Ability to transport liquids in critical states; (7) Cavitation resistance.

4. Casting or Injection Molding:

Casting: Melt the metal and pour it into a mold. After cooling and solidification, remove the pump casing. Casting is suitable for complex structures and large-sized pump casings.

Injection Molding: If the pump casing is made of plastic or other lightweight materials, injection molding can be used. 5. Subsequent Processing: The molded chemical pump casing undergoes shearing, trimming, and inspection to ensure dimensional accuracy and appearance meet requirements.

Heat treatment and surface treatment may also be necessary to improve the casing's hardness, wear resistance, and corrosion resistance.

6. Quality Inspection: Strict quality inspection is performed on the produced pump casings to ensure their dimensions, surface quality, and strength meet requirements. Common inspection methods include dimensional inspection, material inspection, and non-destructive testing.

During pump casing mold production, mold design and manufacturing are crucial. High-precision molds ensure the produced pump casings meet quality requirements. Therefore, selecting an experienced mold manufacturer and ensuring proper mold maintenance are key to improving production efficiency and guaranteeing product quality.