I. Sand Casting.

Sand casting: A casting method that produces castings in sand molds. Steel, iron, and most non-ferrous alloys can gradually be obtained using sand casting.

Technical characteristics:

1. Suitable for making blanks with complex shapes, especially those with complex internal cavities;

2. Wide adaptability and low cost;

3. For some materials with very poor plasticity, such as cast iron, sand casting is the only forming process for manufacturing their parts or blanks.

Applications: Castings such as cylinder blocks, cylinder heads, and crankshafts for automobiles.

II. Investment Casting.

Investment casting: Usually refers to a casting scheme in which a pattern is made from a fusible material, several layers of refractory material are coated on the surface of the pattern to form a shell, and then the pattern is melted and removed from the shell to obtain a mold without a parting surface. After high-temperature firing, sand can be filled and poured. It is often called "lost-wax casting".

Advantages:

1. High dimensional and geometric accuracy;

2. High surface roughness;

3. Capable of casting complex shapes, and the alloys used are unrestricted.

Disadvantages: Complex process, higher cost.

Applications: Suitable for producing small parts with complex shapes, high precision requirements, or those difficult to machine, such as turbine engine blades.

III. Pressure Casting.

Die casting: Uses high pressure to force molten metal at high speed into a precision metal mold cavity. The molten metal cools and solidifies under pressure to form a casting.

Advantages:

1. High pressure and fast flow rate of molten metal during die casting;

2. Good product quality, stable dimensions, and good interchangeability;

3. High production efficiency, and high mold reuse rate;

4. Suitable for mass production, with good economic benefits.

Disadvantages:

1. Castings are prone to small porosity and shrinkage cavities.

2. Die castings have low plasticity and are not suitable for operation under impact loads or vibration.

3. High-melting-point alloy die casting has a short mold life, affecting the expansion of die casting production.

Applications: Die castings were initially used in the automotive and instrument industries, and later expanded to various industries such as agricultural machinery, machine tools, electronics, defense, computers, medical devices, watches, cameras, and daily hardware.

IV. Low-Pressure Casting

Low-pressure casting refers to a method of filling a mold with liquid metal under relatively low pressure (0.02–0.06 MPa) and allowing it to crystallize under pressure to form a casting.

Technical Features:

1. Adjustable pouring pressure and speed, making it suitable for various molds (e.g., metal molds, sand molds) to cast various alloys and castings of various sizes;

2. Bottom-pouring filling ensures smooth molten metal filling without splashing, preventing gas entrapment and erosion of the mold walls and core, thus improving casting yield;

3. Castings crystallize under pressure, resulting in dense structures, clear contours, smooth surfaces, and high mechanical properties, particularly advantageous for casting large, thin-walled parts;

4. Eliminates the need for feeding risers, increasing metal utilization to 90-98%;

5. Low labor intensity, good working conditions, simple equipment, and easy mechanization and automation.

Applications: Primarily traditional products (cylinder heads, wheel hubs, cylinder frames, etc.).

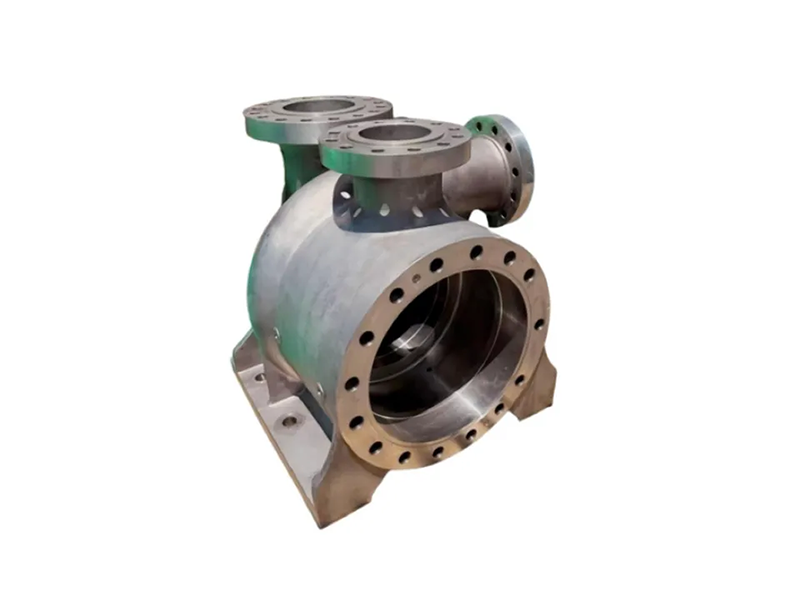

In choosing a casting process, different methods offer unique advantages for different products. Whether it's sand casting, precision casting, or die casting, each process has its specific application areas. Our company focuses on providing customers with high-quality Stainless Steel Pump Casing, employing advanced casting processes and rigorous quality control procedures. With years of extensive casting experience, we can provide customized Stainless Steel Pump Casing solutions to meet the needs of various industries.

Company Advantages:

Advanced Casting Technology: We possess advanced Stainless Steel Pump Casing technology, ensuring stable product quality that meets international standards.

Comprehensive Service: From Stainless Steel Pump Casing design and raw material selection to production, processing, and surface treatment, we provide one-stop service.

Strict Quality Control: Every piece of Stainless Steel Pump Casing undergoes rigorous testing, guaranteeing its durability and safety during use.

Flexible Customization Capabilities: Whether for small-batch production or large-scale orders, we can provide efficient and precise Stainless Steel Pump Casing solutions.

We are committed to always putting customers first, continuously innovating and optimizing the technology and details of Stainless Steel Pump Casing, and striving to become your most trusted casting supplier.