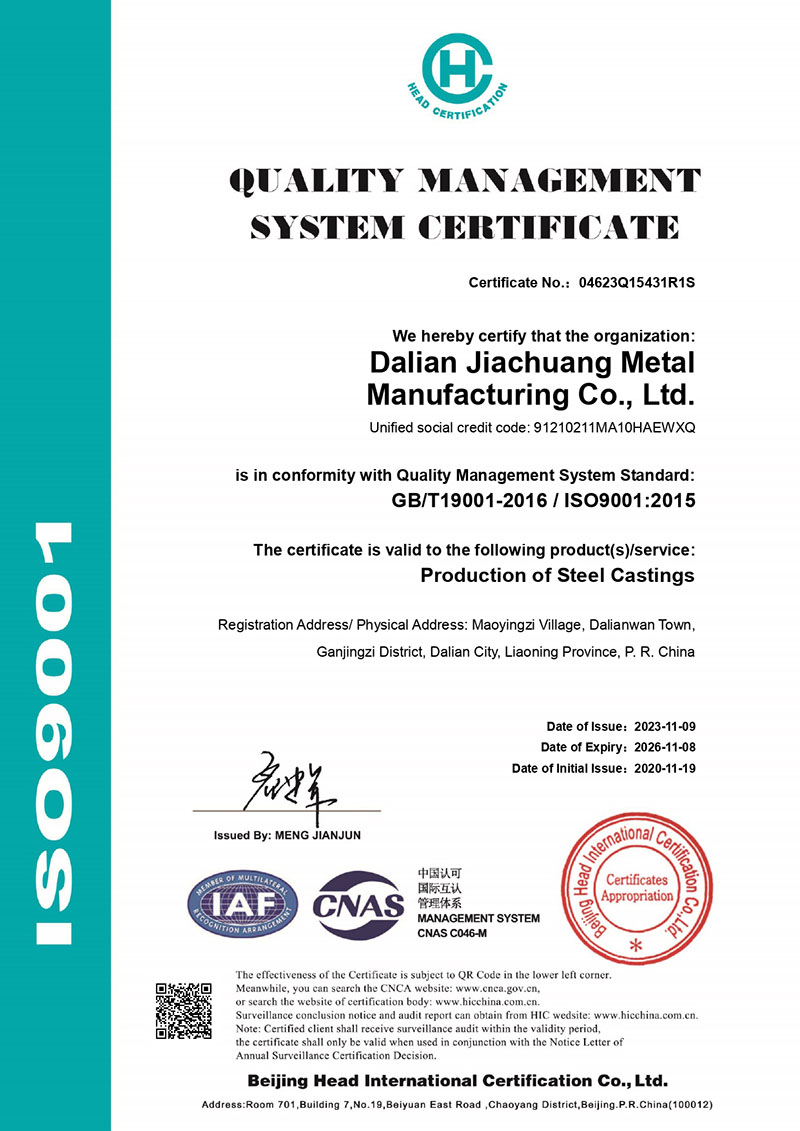

Dalian Jiachuang Metal Manufacturing Co., Ltd. is located in Dalian city, Liaoning Province, covering an area of 30,000 square meters. The main business includes ferrous metal casting, mold manufacturing, mechanical processing, etc.

At present, the company mainly focuses on the casting of fluid machinery parts such as pumps and valves, blowers, compressors, steam turbines and propellers.

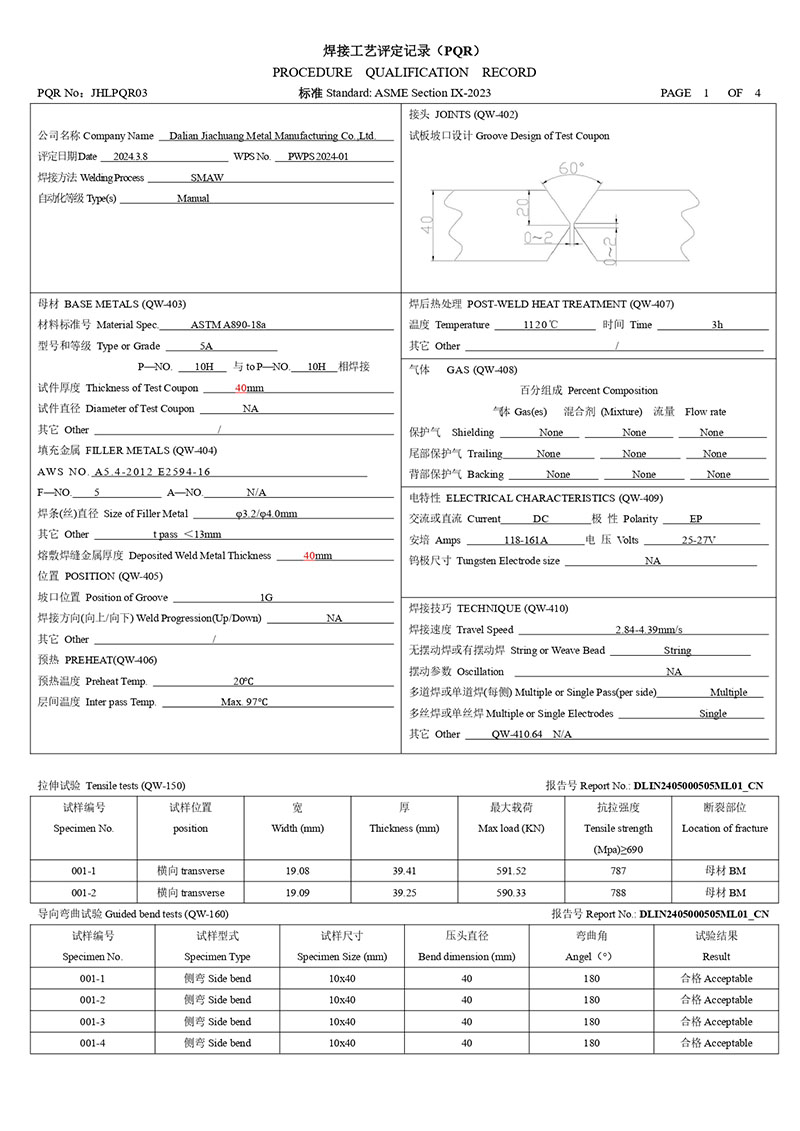

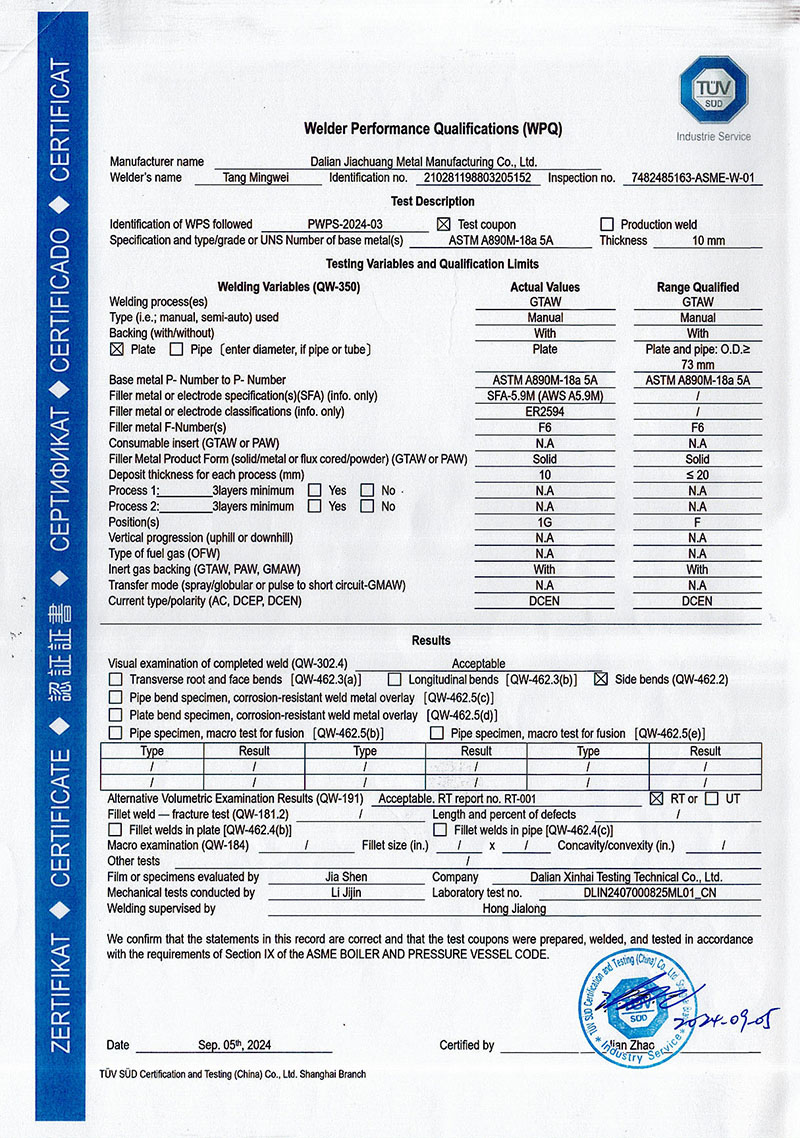

Covering fields such as power (nuclear power, hydro-power, wind power, thermal power), petroleum, petrochemicals, shipping, coal chemical industry, water treatment, cement, LNG, etc. Involves standards of different countries and industries, material standards, and testing standards (GB、ASME/ASTM、EN、ISO、JIS).

Main Material grades incl., Austenitic stainless steel, ferrite stainless steel, martenitic stainless steel, duplex stainless steel, Lewmet, Inconel, Incoloy, Hastelloy, and Monel and other nickel-based alloys, Cr26, Ni-hard and other anti-wear white iron casting, involving corrosion-resistant, wear-resistant, high-temperature resistance and other high-end materials.

After more than four years of rapid development, the company currently has nearly 300 employees, including 2 senior engineers, 8 engineers, and over 30 professional and technical personnel.

We have a production line for alkaline phenolic resin sand (including a 15t/h mobile sand mixer and a 12t/h fixed sand mixer) and a sand treatment production line, multiple 0.5T/1T/3T/5T intermediate frequency induction furnaces, multiple types of shot blasting machines and post-treatment equipment, and complete quality inspection capabilities.

An efficient production mode integrating mold, casting and mechanical processing has been formed to meet customers' one-stop procurement needs.