01-04/2026

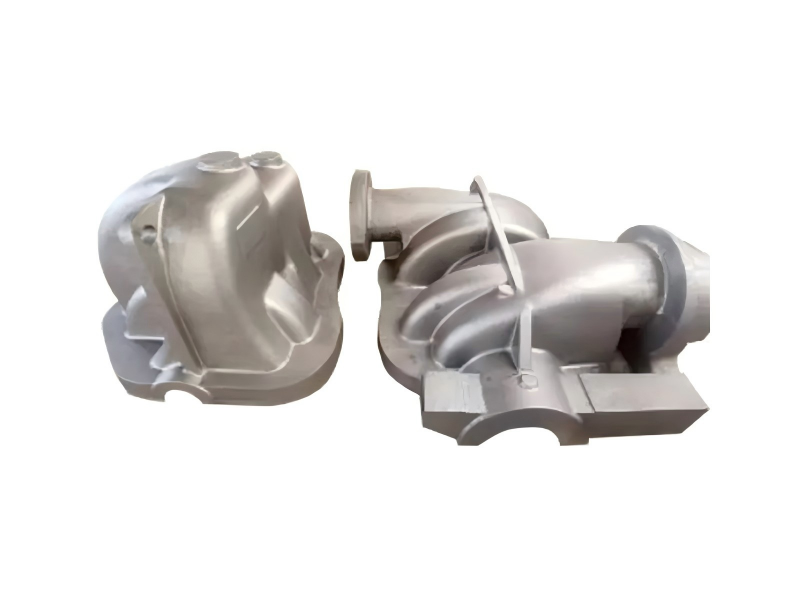

Cast steel sand casting pump bodies are ideal for fine chemical fluid transfer, where corrosive media, high purity requirements, and long-term continuous operation are critical. Compared with cast iron or non-metallic materials, they offer higher structural strength, better impact resistance, and stronger adaptability to acidic and alkaline media through flexible alloy selection. With stable performance under high pressure and heavy loads, these pump bodies help extend service life, reduce maintenance, and ensure safe, reliable operation across fine chemical, petroleum, metallurgical, and power industry applications.