11-12/2025

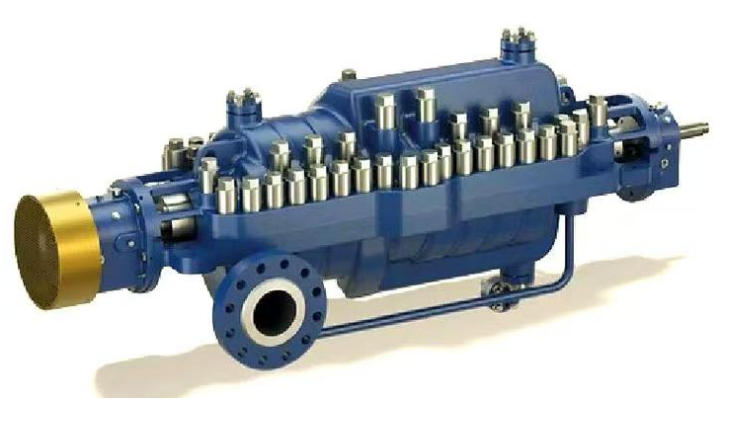

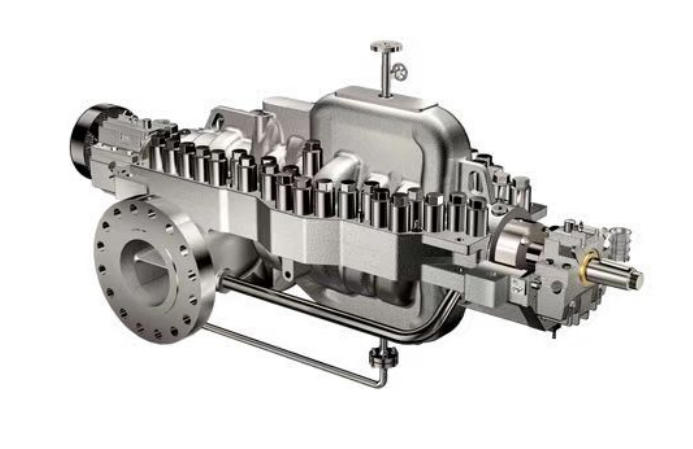

Abstract: This paper focuses on the locations, causes, and improvement measures of cracks that are prone to occur in the pump body of multi-stage pumps during sand casting. Starting from the structure of the multi-stage pump body and combining with the key processes of sand casting, a systematic analysis is conducted. The study indicates that the flange connection area of the multi-stage pump body, the root of the blades, and the areas with sudden changes in wall thickness are the high-risk points for cracks. The main reasons are structural stress concentration, improper casting process control, and the characteristics of stainless steel material. The main text deeply explores the influence mechanism of each process on casting defects (such as cracks), and proposes targeted optimization solutions, including improving the structural design, enhancing the strength of the sand mold, and controlling the pouring parameters. The full text emphasizes reducing the occurrence rate of cracks in the casting pump body through refined operation management and improving the reliability and production efficiency of the stainless steel multi-stage pump body.