Chapter 1 IntroductionSand casting, as a traditional and efficient casting method, is widely used in the production of multi-stage pump bodies. The multi-stage pump casing, as the core component, directly affects the efficiency and lifespan of the pump system. Especially for stainless steel multi-stage pump casings, due to their high corrosion resistance requirements, casting defects such as cracks are prone to occur during the casting process. These casting defects not only increase the scrap rate of the multi-stage pump casing but also increase production costs. The cracking phenomenon of the casting pump casing is particularly prominent in industrial practice, often occurring in the weak areas of the multi-stage pump casing. This article will start from the analysis of the structure of the multi-stage pump body, discuss how each process (casting, core making, box assembly, pouring) of sand casting can cause casting defects, and propose improvement measures.The geometric characteristics of the multi-stage pump casing determine the prone locations of cracks. The casting pump casing is usually composed of multiple impeller chambers and has a complex structure with significant wall thickness variations. During the casting process of stainless steel multi-stage pump casings, due to the high thermal expansion coefficient, thermal stress cracks are prone to occur. The cracking problem in the casting defects, accounting for up to 30% of the total, needs to be controlled at the source. For example, the flange connection area of the multi-stage pump casing often develops cracks due to stress concentration, affecting the sealing performance of the casting pump casing. Additionally, the metallurgical characteristics of the stainless steel multi-stage pump casing exacerbate the risk of casting defects. The subsequent chapters of this article will further analyze the structural analysis and process steps to ensure that each keyword (casting pump casing, multi-stage pump casing, stainless steel multi-stage pump casing, casting defect, crack) is repeated, thereby strengthening the theme.The production of the casting pump casing requires optimizing the structural design to prevent cracks. The overall strength of the multi-stage pump casing depends on the accuracy of the sand casting process. The causes of casting defects such as cracks involve multiple aspects, and improper process control is the key. For example, the uneven sand mold compactness in the casting process is prone to cause crack defects in the multi-stage pump casing. Similarly, the insufficient strength of the sand core in the core-making process may lead to internal cracks in the stainless steel multi-stage pump casing. Incorrect assembly in the box assembly process will exacerbate the casting defects, while the temperature control during the pouring process directly causes the expansion of cracks in the casting pump casing. The subsequent analysis will systematically elaborate on these points to help operators reduce the occurrence rate of crack defects in the stainless steel multi-stage pump casing and improve the quality of the casting pump casing.The cracking problem of the casting pump casing is not limited to the statistics of casting defects; it also needs to be combined with the application background of the multi-stage pump casing. Stainless steel multi-stage pump casings are widely used in the chemical industry, and their crack defects can lead to leakage accidents. Therefore, identifying the high-risk areas of crack occurrence in the multi-stage pump casing is crucial: the blade root, flange interface, and corner areas of the casting pump casing often develop cracks due to structural changes. The prevention of casting defects should start from structural optimization and be combined with process improvements.

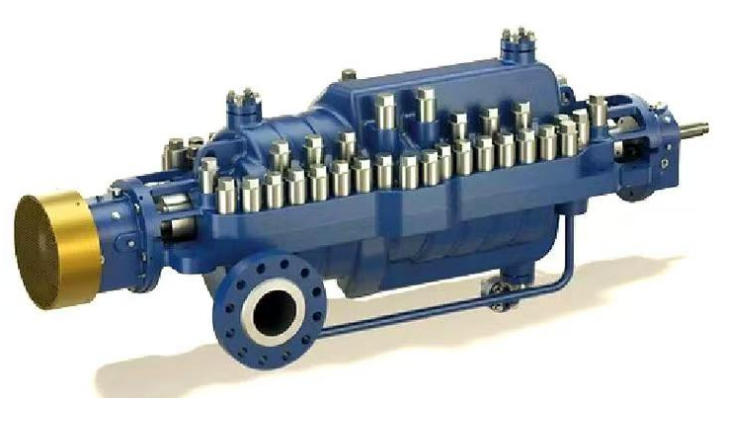

Chapter 2: Analysis of the Pump Body Structure of Multi-stage PumpsThe structural characteristics of the pump body of multi-stage pumps are the primary factor causing cracks. The pump body of multi-stage pumps is composed of multiple series-connected impeller chambers and is complex in design with variable geometric shapes. The typical structure of the cast pump body includes the inlet flange, outlet flange, blade support area, and the outer shell. The stainless steel multi-stage pump body, due to its material properties (such as high chromium and nickel content), is sensitive to thermal stress during casting and prone to cracking defects. The flange connection area of the multi-stage pump body is a high-risk location for cracks because the wall thickness changes abruptly, leading to stress concentration. The root of the ribs of the cast pump body also often develops cracks, due to the small structural corner radius and uneven metal contraction during casting.The structural weak points of the stainless steel multi-stage pump body exacerbate the risk of casting defects. The outer shell of the multi-stage pump body usually adopts a thin-walled design to reduce weight, but during casting, this area is prone to form tensile stress cracks when the metal solidifies and contracts. If the corner of the casting pump body is designed as an acute angle, the casting defects will increase significantly. For example, if the transition zone between the flange and the pump body of the multi-stage pump is not rounded, the probability of cracks in the casting defects is as high as 40%. The material factors of the stainless steel multi-stage pump body cannot be ignored either: high alloy content leads to thermal brittleness, and improper cooling speed after pouring can easily generate microcracks on the surface of the casting pump body.The location of the cracks in the cast pump body is related to the function of the multi-stage pump body. The stainless steel multi-stage pump body needs to withstand high-pressure fluids and has high structural strength requirements. The blade support area of the multi-stage pump body often develops crack defects due to frequent dynamic loads. The casting defect analysis shows that the areas with uneven wall thickness (such as the transition from thick to thin walls) are prone to generate thermal cracks. The metallurgical defects (such as inclusions) of the stainless steel multi-stage pump body will amplify the casting defects. For example, the cracks in the cast pump body often start at the structural stress points in sand casting and spread throughout the entire body. Improving the structural design of the multi-stage pump body is the basis for preventing casting defects: increasing the radius of the rounded corners, optimizing the distribution of wall thickness can reduce the risk of cracks in the cast pump body.The structural analysis of the multi-stage pump body needs to be combined with the sand casting process. The cracking problem of the cast pump body is not only related to the design but also interacts with subsequent processes. The long-sized structure of the stainless steel multi-stage pump body has a large contraction amount during cooling, which is prone to cause casting defects at the box-fitting or pouring stage. Casting defects such as cracks in the multi-stage pump body should be identified first in production to avoid cost losses.In summary, the improvement directions for the cast pump body include: strengthening the flange area, rounding the root of the blades, and uniforming the overall wall thickness. These measures can reduce the internal stress of the stainless steel multi-stage pump body and inhibit the formation of casting defects. The crack prevention of the multi-stage pump body begins with structural optimization, and the subsequent chapters will discuss the influence of process factors.

Chapter 3: Analysis of the Impact of Molding Processes on CracksThe molding process is the first step in sand casting and directly affects the surface quality and internal structural integrity of the casting pump housing. Improper molding operations can lead to casting defects in multi-stage pump housings, especially cracks. During the molding process, uneven compactness of the sand mold is one of the main causes of cracks in multi-stage pump housings. Insufficient compactness of the casting cavity in the pump housing results in the erosion of sand particles by the molten metal during pouring, forming casting defects such as surface cracks. The mold sand for stainless steel multi-stage pump housings has higher requirements: excessive or insufficient moisture in the mold sand will increase the risk of casting defects. For example, when the surface layer strength of the mold sand is low, the flange area of the stainless steel multi-stage pump housing is prone to thermal cracks.The preparation of the sand mold in the molding process of multi-stage pump housings requires strict control. Cracks in the casting pump housing often result from sand mold stratification or air holes during molding. Improper sand ratio in the mold sand for stainless steel multi-stage pump housings (such as insufficient binder) will lead to a decrease in mold sand strength, resulting in more casting defects after pouring. Errors in model removal during molding may also damage the mold, causing local cracks in the multi-stage pump housing. Poor air permeability of the mold sand for the casting pump housing will increase gas retention, forming internal cracks in casting defects.The optimization of the molding process for stainless steel multi-stage pump housings can reduce casting defects. The key areas of the multi-stage pump housing (such as the root of the rib plates) require high compactness sand molds. In the production of casting pump housings, controlling the moisture content of the mold sand within the range of 4-6% can reduce shrinkage stress and prevent cracks. The mold sand preparation for stainless steel multi-stage pump housings should avoid sharp edges and corners to reduce the origin of casting defects. The operation suggestions include: ensuring uniform compactness with automated molding equipment and strengthening corner treatment during manual molding. These measures can significantly reduce the incidence of cracks in the multi-stage pump housing. The prevention and control of casting defects such as cracks on the multi-stage pump housing requires the molding process to prioritize strengthening mold support.

Chapter 4 Analysis of the Impact of Core-making Process on CracksThe core-making process focuses on the production of sand cores, which support the internal cavities of the multi-stage pump casing and directly affect the occurrence of casting defects. Improper core-making operations are an important cause of cracks in the casting pump casing. When the sand core strength is insufficient, the blade cavity area of the multi-stage pump casing is prone to collapse, resulting in internal cracks. The sand core of the stainless steel multi-stage pump casing requires high refractory properties; otherwise, thermal expansion will cause casting defects. Incorrect core binder ratio can lead to brittle cracking of the sand core, and after pouring, a crack will appear in the stainless steel multi-stage pump casing.The core-making process of the casting pump casing requires consideration of sand core exhaust design. The complex structure of the multi-stage pump casing requires a reasonable layout of sand core exhaust holes; otherwise, the accumulation of gas pressure will cause casting defects such as cracks. Insufficient drying of the sand core of the stainless steel multi-stage pump casing (with residual moisture) will generate steam pressure during pouring, resulting in subsurface cracks in the casting pump casing. Damage during core-making handling also exacerbates the crack problem, and the damaged points of the sand core of the multi-stage pump casing will become the source of casting defects.The improvement measures for the core-making of the stainless steel multi-stage pump casing include: selecting high-strength core sand and optimizing the exhaust system. In the production of the casting pump casing, uniform coating of sand core paint can enhance refractoriness and reduce cracks. The core-making process of the multi-stage pump casing should be regularly tested for sand core strength to prevent casting defects.

Chapter 5: Analysis of the Impact of the Box-Molding Process on CracksThe box-molding process involves the combination of sand molds and sand cores. Errors in the operation can directly lead to casting defects in the multi-stage pump housings. Improper box-molding can result in misalignment of the sand cores or compression of the sand molds, causing stress cracks at the corners of the cast pump housings. The box-molding of stainless steel multi-stage pump housings requires precise alignment; otherwise, uneven thermal stress will exacerbate the casting defects. If the floating sand is not cleaned thoroughly during the box-molding process, sand particles will embed in the surface of the multi-stage pump housings, forming casting defects such as crack sources.The box-molding operation of stainless steel multi-stage pump housings emphasizes gap control. In the production of casting pump housings, excessive or insufficient clearance between the core heads causes stress concentration, leading to casting defect cracks. Uneven box-molding pressure for the multi-stage pump housings will cause deformation of the sand molds, increasing the risk of cracks in the flange area of the stainless steel multi-stage pump housings. Improvement measures include: using locating pins to ensure accuracy and strengthening the cleaning procedure.

Chapter 6 Analysis of the Influence of Pouring Process on CracksThe pouring process controls the filling of the molten metal. Improper parameters are the main cause of cracks in the multi-stage pump housing. When the pouring temperature is too high, the thermal stress of the cast pump housing increases, resulting in casting defects such as hot cracks. The excessive pouring speed of the stainless steel multi-stage pump housing causes the molten metal to wash the sand mold, resulting in surface cracks. Casting defects are more likely to occur when the pouring is interrupted. The uneven solidification of the multi-stage pump housing leads to internal cracks.The optimization of the pouring process for the stainless steel multi-stage pump housing includes: controlling the temperature at 1570-1560°C and using a bottom-feed system. These measures can reduce the crack defects in the cast pump housing.

Chapter 7 Comprehensive Improvement MeasuresBased on the structural analysis and each process, the improvement measures include: strengthening the multi-stage pump housing design (such as rounding the flange corners); optimizing the tightness of the mold shape; enhancing the core-making strength; strictly aligning the boxes; controlling the pouring parameters. After implementation, it can effectively reduce the occurrence of crack defects in the stainless steel multi-stage pump housing and improve the production efficiency of the cast pump housing.

Chapter 8 ConclusionThe crack problem in the pump body of the multi-stage pump in sand casting stems from structural weaknesses and process errors. Through structural optimization and process control, the casting defects such as cracks in the casting of the stainless steel multi-stage pump housing can be effectively prevented.