Recently, Dalian Jiachuang Metal Manufacturing Co., Ltd. (hereinafter "Jiachuang Metal") has made a critical breakthrough in sand casting of steel casting impellers—the core of OH pumps—via independently developed patents. Third-party tests show its impeller qualification rate rose from the industry’s 85% to 99%, with delivery cycle cut by 40%. This leap helped it win orders from a domestic shipbuilding heavy industry and a large coal chemical firm, plus the customized HX0012 energy project order (requiring impellers for high-pressure, high-corrosion environments). The achievement fills Northeast China’s high-end pump casting gap and shows local SMEs’ innovation in industrial upgrading.

Founded in July 2020, Jiachuang Metal focuses on ferrous casting and pump valve manufacturing. It built a "casting-processing-testing-sales" full-chain system to meet customer needs. With import-export qualifications, its products serve domestic oil, water treatment, and power sectors, and provide custom solutions for Southeast Asian pump makers via technical cooperation. After five years, it has 14 national patents (3 core invention patents), 5 software copyrights, and 3 certificates (ISO9001, Special Equipment Manufacturing License), solidifying its edge in OH pump and multi-stage pump impellers.

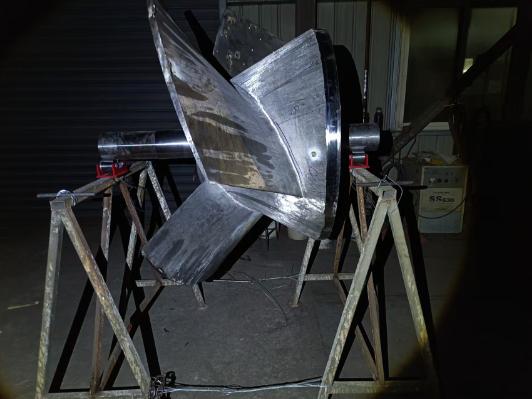

In industry, OH pumps (vertical cantilever centrifugal pumps) handle harsh conditions: high-temperature media (up to 300℃), high-pressure fluids (up to 8MPa), and corrosives. As OH pumps’ "power core," steel impellers determine efficiency, energy use, and lifespan. Jiachuang Metal’s impellers use ZG230-450 (general use) and CE3MN (corrosion-resistant) high-strength steel, fitting OH pumps with 50-500m³/h flow and 50-300m lift—suitable for oilfield sulfur crude transport and water plant sludge pressurization. However, traditional sand casting struggles with their complex structure: 8mm minimum flow channel width and 3mm thin blades, causing mold-stripping flow channel damage and post-pouring blade air cracks—longtime industry pain points.

To solve this, Jiachuang Metal’s team developed patented impeller steel casting molds with dual-valve pressure control. First/second valves in the upper sand box regulate sand mold air pressure for stability. A constant-temperature heat dissipation channel in the mold base keeps curing temp at 75-80℃, avoiding cracks from temperature differences (a traditional mold flaw). Tested in dozens of batches, the mold controls flow channel accuracy within ±0.2mm, fixing traditional mold issues. "Since using these molds, efficiency and quality improved," said a Jiachuang Metal official. "In June 2025, we won two energy enterprise mold orders worth 8.6 million yuan—up 120% year-on-year."

While boosting precision, Jiachuang Metal advanced green, efficient sand casting. Its patented steel sand recycling device uses three-stage filtration: PP filter, magnetic iron removal, and hot air drying. It removes impurities/binders, keeps sand moisture below 1.5%, and raises recycling rate from 60% (traditional) to 96%. This cuts annual new sand purchases by 300 tons and costs by 38%, benefiting environment and economy. In smelting, its patented metal casting furnaces have 3-ton movable pouring trolleys and intelligent temp control. The system adjusts induction furnace power (500-800kW) and pouring speed (0.5-1.2m/s) for steel types, increasing molten steel uniformity by 25% and reducing blade performance unevenness. Tests show 3mm blade air defect rate dropped from 5.2% to <0.3%, with tensile strength ≥450MPa and elongation ≥20% (meeting GB/T 11352-2022).

With innovation-driven advantages, Jiachuang Metal built a full-chain system: casting, CNC machining (high-precision blade finishing), and testing (ultrasonic NDT, dynamic balance). Of 14 patents, 7 serve pump production (mold, sand treatment, smelting)—forming a high-end impeller technical barrier. Since 2025, it joined 30 domestic bids, winning high-end orders: HX0012 (coal gasification long-term use) and shipbuilding heavy industry marine OH pump impellers (ballast water system, strict corrosion/ stability demands). These expand its market share and reputation.

Experts note Jiachuang Metal’s patent-based solution proves "patents empower manufacturing." Focusing on segmented product pain points with "small but precise" patents suits resource-limited SMEs. As part of Liaoning’s equipment industry, its upgrade offers a replicable model for Northeast China’s traditional casting sector, driving local high-quality development and regional equipment industry vitality.