1. Sulzer has launched the brand-new Scaba STA series of vertical mixers

Recently, Sulzer announced the launch of its new Scaba STA series of vertical mixers, specifically engineered for industrial mixing applications to deliver exceptional reliability and enhanced sustainability.

The Scaba STA series achieves superior energy efficiency through advanced hydraulic design, typically reducing energy consumption by 20% compared to conventional mixers. Given its estimated operational lifespan of 30 years, this innovation is expected to provide significant long-term energy savings for end users.

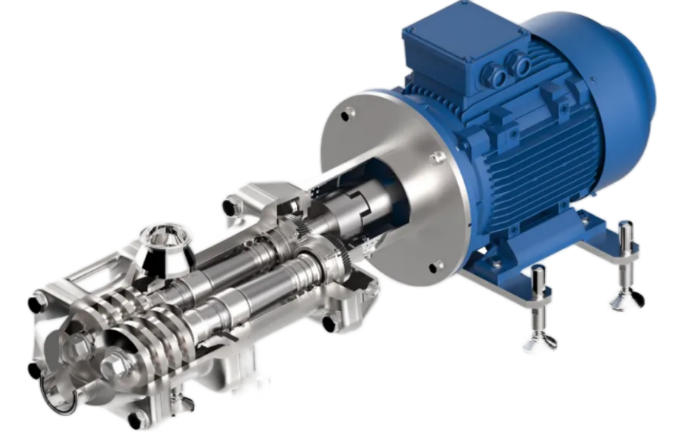

2. Wangen has improved the design of the NG series twin-screw pumps

The NG series twin-screw pumps from Wangen are specifically engineered for the reliable handling of fluids with viscosities ranging from low to high, including volatile and gaseous media. These pumps meet the most stringent hygiene and efficiency requirements, making them ideal for demanding industrial applications.

This solution has been rigorously validated as a sanitary pumping system, delivering superior performance and an extended service life. It enhances equipment uptime and reduces lifecycle costs for customers in the food, pharmaceutical, and cosmetics manufacturing sectors.

Available in multiple configurations, this pump series supports a maximum flow rate of up to 200 m³/h and a maximum differential pressure of 25 bar.

3. Armstrong Fluid technology established an industrial sector

Recently, Armstrong Fluid Technology Company has launched the Armstrong Industrial Division, a dedicated unit designed to consolidate the company’s industrial expertise into a streamlined and integrated solution.

By combining the Armstrong gas transmission system with the RMI pressure system, the Industrial Division will be better positioned to address the fluid and gas pumping requirements of diverse industries—including mining, food processing, energy, and manufacturing—with enhanced precision and efficiency.

The new division is structured into two specialized teams, each focused on distinct technical domains: fluids and gases. The fluids team will support applications in metal casting, non-metal manufacturing, glass production, papermaking, food processing, and mining, while the gases team will serve the oil and gas industry, as well as the energy and utilities sectors.

4. Grundfos Connect Sewer Insight system has been officially launched in the United States

Grundfos recently officially launched its Connect Sewer Insights system in the United States, a new digital platform for monitoring and optimizing open channel flow systems.

Powered by machine learning and powerful data analytics, the platform provides utilities and municipalities with real-time visibility, predictive insights, and proactive tools to locate wastewater inflow and infiltration (I&I), optimize operations and maintenance processes, and prevent overflows.

Grundfos Connect Sewer Insights is designed to address the challenges of wastewater overflows in the context of aging infrastructure, extreme weather conditions, and operational constraints.

The launch of GCSI follows Grundfos' 2023 acquisition of remote monitoring solutions provider Metasphere, which has now been integrated into the Grundfos Connect brand. This marks a key step in Grundfos' transformation into a comprehensive digital solutions provider for the water industry.

5. Armstrong has launched an energy-saving variable-speed dry rotor circulation pump

Armstrong Fluid Technology has introduced two new models in its Compass R circulator pump series—the 40-85 and 60-50.

The Compass R is an energy-efficient, variable-speed, dry-rotor circulator pump. Designed to replace existing fixed-speed circulator pumps, it serves as a universal, energy-efficient upgrade across its capacity range and mounting configurations. Customers can choose the Compass R circulator pump to meet applications requiring up to 60 feet of head.

New features of the Compass R include a permanent magnet motor with Design Envelope variable-speed technology; Posi-Start technology for smooth starting and pump protection; bolt-to-bolt compatibility with a wide range of installed base circulator pumps; and quick-release clamps for easy servicing. Other features include a reduced carbon footprint, easily accessible terminal blocks, an optimized hydraulic system with a high-efficiency dry-rotor design, and multiple control options, including automatic mode, simplifying selection and commissioning.