In modern industrial systems, stainless steel impeller castings serve as core components of fluid machinery, playing a vital role in energy conversion and medium transportation. From high-corrosion medium pumps in chemical processes to high-temperature, high-pressure ventilation systems in power generation, and sewage treatment equipment in environmental engineering, these castings ensure efficient, stable, and long-term operation of entire systems through their superior performance. This article systematically explores the key technical aspects and industrial applications of stainless steel impeller castings from dimensions including structural design, material properties, advanced manufacturing processes, diverse applications, and technological development trends.

I. Structural characteristics of stainless steel impeller casting

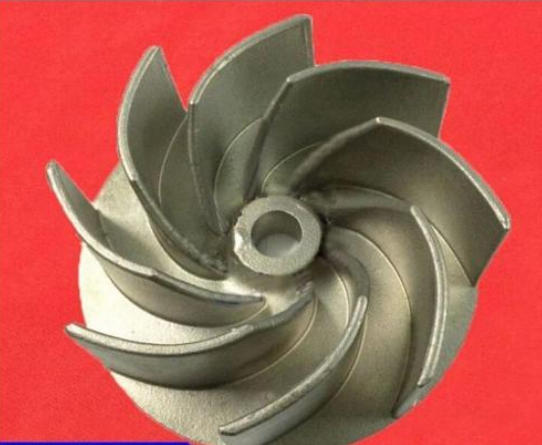

The structural design of stainless steel impeller directly determines the aerodynamic performance, hydraulic efficiency and operation stability of fluid machinery. A typical impeller is composed of three parts: blade, hub and cover plate. Its design should take into account the requirements of fluid mechanics and structural mechanics.

(I) Blades

Blades are the core components for fluid energy conversion, where profile design, installation angle, and blade count significantly influence pump efficiency, cavitation performance, and operational noise. Common blade types include backward-curved, forward-curved, and radial designs. Backward-curved blades are commonly used in centrifugal pumps due to their high efficiency and low noise levels, making them suitable for medium-to-high flow applications. Forward-curved blades are primarily employed in high-pressure fans, offering slightly lower efficiency but higher single-stage pressure rise. Radial blades are particularly suited for specialized fluid machinery like vacuum pumps.

The determination of the number of blades should take into account the flow uniformity, turbulent loss and anti-clogging requirements. Generally, the impeller of a clear water pump adopts 6-8 blades; when conveying media containing solid particles, the number of blades can be reduced appropriately to reduce the risk of wear.

(II) Wheel hubs

As the key load-bearing structure connecting blades to the main shaft, hub design must meet torque transmission and rigid support requirements under high-speed conditions. Increasing hub diameter and optimizing hub profile are commonly used to improve rotor dynamic stability, which is particularly critical in large high-speed impellers.

(III) cover plate

The impeller consists of front and rear plates that form a flow channel, minimize internal leakage, and reduce eddy current losses. The closed-type impeller features complete sealing with both front and rear plates, delivering high efficiency for clean media applications. The semi-open type, which only requires a rear plate, offers enhanced flow capacity and better clogging resistance, making it suitable for handling media containing particles or fibers.

II.Second, the material characteristics of stainless steel impeller castings

Stainless steel material with its excellent corrosion resistance, high strength and good thermal stability, has become the preferred material for impeller manufacturing, especially suitable for harsh industrial environment.

(1) Corrosion resistance

By incorporating alloying elements such as chromium (Cr), nickel (Ni), and molybdenum (Mo), stainless steel surfaces can form a dense passive film that effectively resists corrosive media. For instance, 304 stainless steel (0Cr18Ni9) is suitable for general corrosive environments and food industries; 316 stainless steel (0Cr17Ni12Mo2), containing molybdenum, demonstrates superior resistance to pitting and crevice corrosion, making it widely used in chemical and marine environments; duplex stainless steels like 2205 combine austenitic and ferritic phases, offering high strength and resistance to chloride-induced stress corrosion cracking.

(II) High mechanical strength and toughness

Stainless steel impeller materials must not only be corrosion-resistant but also possess high strength and excellent toughness to withstand centrifugal forces and fluid loads during high-speed rotation. For instance, precipitation-hardened stainless steel (17-4PH, 0Cr17Ni4Cu4Nb) can achieve tensile strength exceeding 1000 MPa through heat treatment, making it commonly used in high-stress impeller components.

(III) excellent high temperature performance

In high-temperature applications (such as boiler feedwater pumps and heat medium circulation pumps), impeller materials must demonstrate excellent oxidation resistance and creep strength at elevated temperatures. 310S stainless steel (0Cr25Ni20), with its high chromium-nickel content, can maintain stable operation below 1200℃ for extended periods, making it the ideal material choice for high-temperature impellers.

III, the manufacturing process of stainless steel impeller casting

The manufacturing of stainless steel impeller casting is a multi-process precision forming process, including mold design, melting and pouring, heat treatment and precision machining.

(1) Mold design and manufacture

The CAD/CAE design of impeller molds is carried out based on fluid simulation and finite element analysis, optimizing the gating system, cooling scheme, and riser design. The mold materials are mostly selected from H13 and other hot-working mold steels, with five-axis CNC machining and EDM processes ensuring cavity precision and surface quality.

(II) Smelting and pouring

Smelting: medium frequency induction furnace or AOD furnace is used for refining, C, S, P and other impurity elements are strictly controlled, and the purity of molten steel is improved by argon deoxidation process.

Pouring: gravity casting, low pressure casting or centrifugal casting can be selected according to the structure of impeller. Centrifugal casting is especially suitable for axially symmetric impeller, which can significantly improve the material density and mechanical properties.

(III) Post-treatment and finishing

Heat treatment: austenitic stainless steel is usually treated by solution (1050-1150℃ water quenching) to eliminate casting stress and optimize corrosion resistance; precipitation hardened steel is treated by aging to improve strength.

Mechanical processing: the impeller needs to be processed by turning, milling, grinding and other processes to complete the precision processing of flow channel line and installation surface, so as to ensure the dynamic and static balance and assembly accuracy.

Surface treatment: electrolytic polishing, passivation or spraying special coating are often used to further improve the corrosion resistance and anti-cavitation performance.

IV. Application fields of stainless steel impeller castings

(I) Chemical industry

Used for corrosion resistant centrifugal pumps, agitators and compressors, such as 316L impeller suitable for chlor-alkali industry and organic acid transportation.

(II) Energy and electricity

Covering boiler feed pump, steam turbine and wind power cooling system, the material is required to have high temperature resistance, corrosion resistance and anti-micro vibration and wear resistance.

(III) Environmental protection and water treatment

It is widely used in sewage lifting pump, aeration fan and desulfurization circulating pump, and needs to deal with the complex chemical composition and wear and corrosion coexistence environment.

(IV) Food and pharmaceuticals

Austenitic stainless steel (such as 304,316) is the first choice for food pumps and sanitary mixing equipment due to its non-toxic, corrosion resistant and easy to clean characteristics.

(V) Oceans and ships

The 316L and duplex stainless steel impellers are excellent for use in desalination plants, ballast water pumps and fire pump systems.

V, the development trend of stainless steel impeller casting

(1) Research and development of new materials

High alloy super stainless steel, metal matrix composites and custom alloys will be gradually promoted to adapt to extreme corrosion and high temperature environments.

(II) Precision manufacturing and digitization

Additive manufacturing (3D printing) technology has been applied to the integrated molding of complex impellers; AI based flow channel optimization and digital twin technology have further improved performance.

(III) Green manufacturing and remanufacturing

Promote low-carbon smelting process, strengthen the recycling and remanufacturing technology of waste impellers, and support resource recycling.

(IV) Customization and intelligent operation and maintenance

Provide integrated material-structure-process solutions based on working conditions, and integrate sensors to realize online monitoring and predictive maintenance of impeller status.

epilogue

As the "heart" of industrial fluid equipment, stainless steel impeller castings demonstrate the advanced manufacturing sector's relentless pursuit of integrated capabilities in materials, processes, and design. Looking ahead, with growing demands for green, low-carbon solutions and smart manufacturing, these castings will continue advancing toward high performance, exceptional reliability, and extended service life. This evolution will provide essential support for critical industrial applications across various sectors.