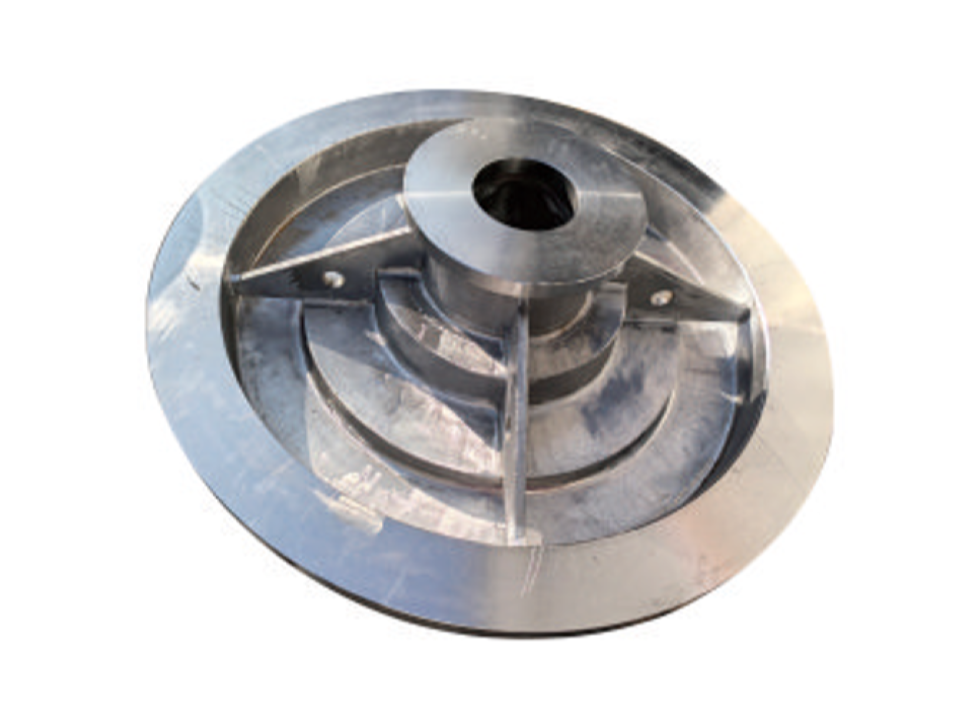

Introduction of end suction pump casing casting:

End suction pump casing casting is a housing component of the end suction pump, located at the drive end of the pump. End suction pump casing casting has the function of closing the pump chamber, supporting the bearing, bearing the pressure, and providing a maintenance channel.

Features of casting chemical pump cover:

1. Casting chemical pump cover can also operate stably under harsh working conditions in chemical, petroleum, seawater treatment and other industries, providing reliable protection for end-suction pumps.

2. When the casting chemical pump cover is subjected to accidental shock or vibration, it can maintain the integrity of the structure and ensure the safe operation of the end suction pump.

3. The duplex stainless steel material used in casting chemical pump cover can be recycled and reused, which meets the environmental protection requirements of modern industry.

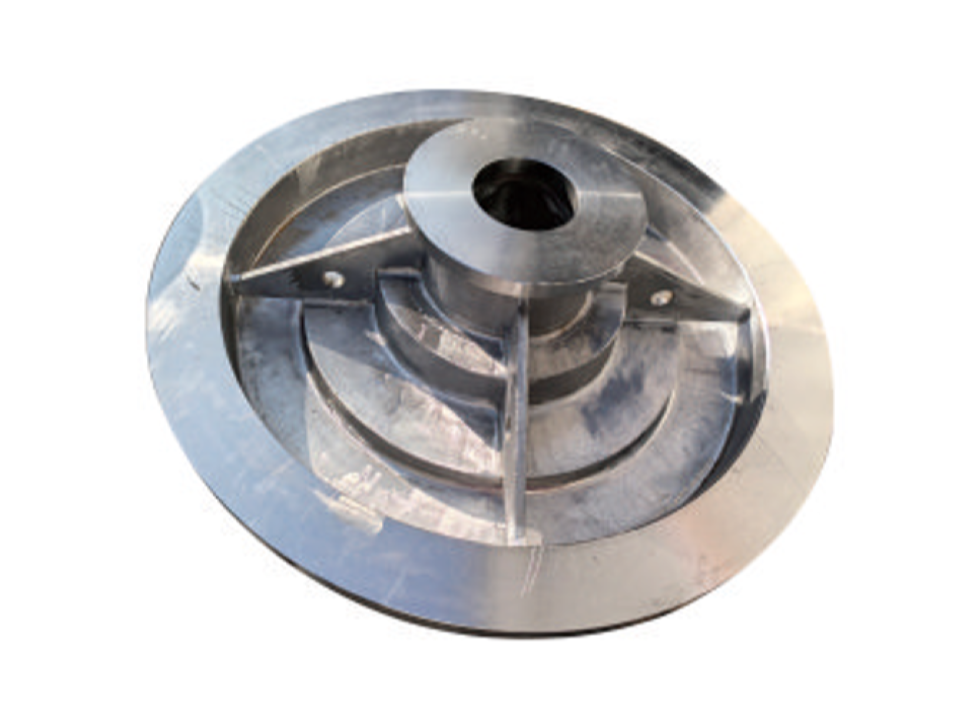

Maintenance of casting chemical pump cover:

1. Regularly clean and check the casting chemical pump cover: during daily maintenance, wipe the surface of the casting chemical pump cover with water or neutral cleaning agent to remove media residues and prevent long-term attachment of corrosive media, and check the surface of the casting chemical pump cover for scratches, cracks or corrosive spots. If a problem is found, it should be repaired in time.

2. Maintenance of the sealing surface of the wear resistant casting pump cover: the sealing surface of the wear resistant casting pump cover needs to be kept flat and free of foreign objects. After each disassembly, you can use professional tools to clean up the remaining gasket debris or media crystals on the sealing surface, and if necessary, you can use abrasive paste to repair minor scratches.

Use of wear resistant casting pump cover:

1. Chemical industry: in various chemical production processes, wear resistant casting pump cover is used to transport highly corrosive chemical raw materials such as sulfuric acid, hydrochloric acid, and sodium hydroxide.

2. Oil and gas industry: in the process of oil extraction, refining, and natural gas treatment, wear resistant casting pump cover is usually used in end-suction pumps that transport crude oil, petroleum products, sulfur-containing sewage and other media, and can withstand complex chemical environments and high-pressure working conditions.

3. Power industry: in the desulfurization and denitration system of thermal power plants, the wear resistant casting pump cover needs to transport a slurry containing acid and alkali components.

4. Environmental protection industry: sewage treatment plants use wear resistant casting pump cover when treating sewage containing heavy metals, organic matter and other pollutants.

Customized service:

Our company can provide customized service. You can send us your detailed drawings and purchase requirements to ensure that the product is highly compatible with your needs.

About us:

Dalian Jiachuang Metal Manufacturing Co., Ltd. always puts the needs of customers first, and takes customer satisfaction as the standard of work. Our team will try our best to solve problems for customers and provide timely support and services. If you like our company or products, you can contact us at any time and look forward to your message!