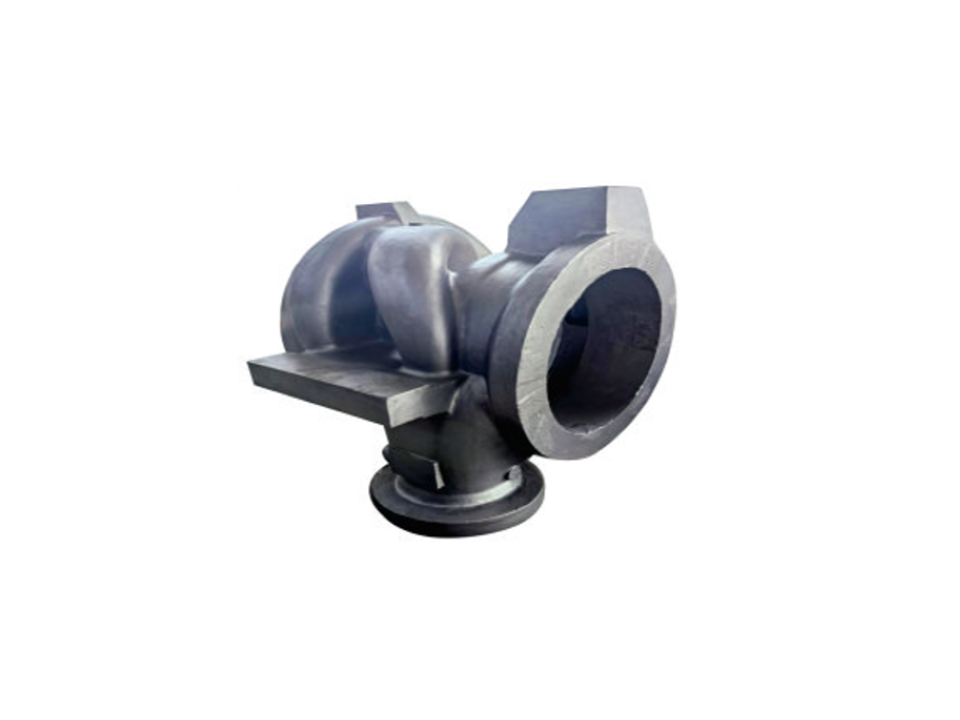

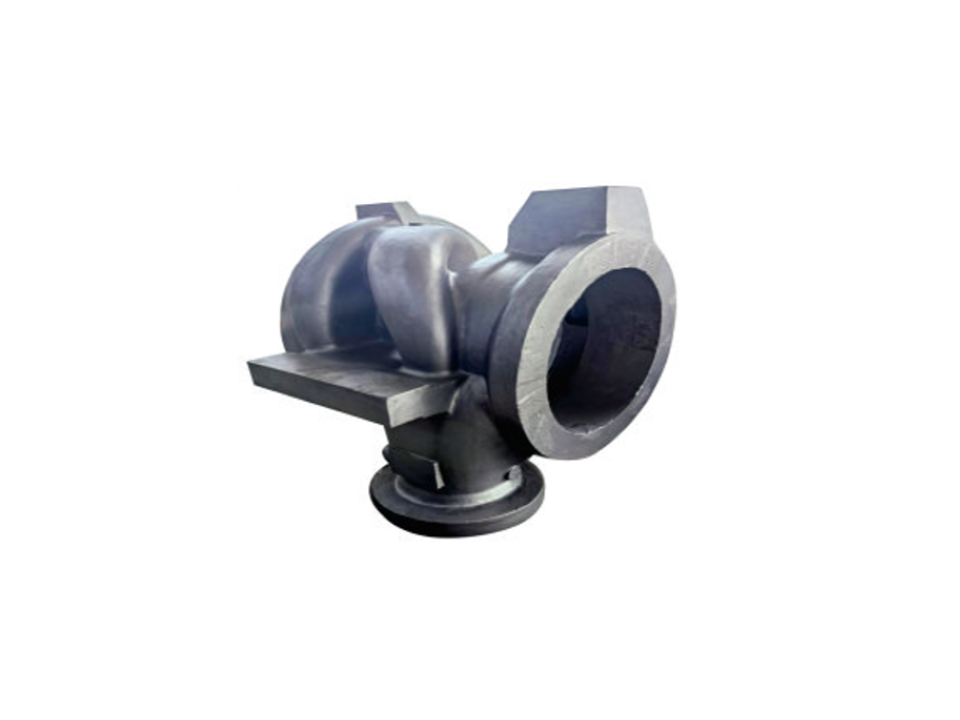

Introduction of radial split casing:

Radial split casing is one of the important structural components of centrifugal pumps and multistage pumps. The main function of radial split casing is to form a fluid delivery channel and withstand the pressure of the delivery medium, and provide installation support for components such as the impeller and shaft system. Radial split casing is widely used in industrial fields, municipal engineering and mining work scenarios.

Features of radially split pump body:

1. Radially split pump body has a uniform wall thickness and has passed the hydrostatic test. It can withstand long-term working pressure, ensure stable operation under high-pressure working conditions, and reduce the risk of various damage to the structure caused by pressure overload.

2. Radially split pump body adopts simulation analysis in the process design to solve the internal defects of castings, which improves the operating efficiency of the equipment while ensuring product quality.

3. The radially split pump body is easy to disassemble, and there is no need to move the motor when replacing parts, which can shorten the maintenance time and reduce production losses.

Application scenarios of radially split pump body:

1. Power industry: radially split pump body is widely used in condensate pumps and other equipment in thermal power plants and nuclear power plants.

2. Chemical industry: radially split pump body is widely used in chemical media transfer pumps and other equipment.

3. Municipal field: radially split casing pump is widely used in equipment such as rainwater drainage pumps and urban water supply pressurized pumps.

How to maintain radially split casing pump:

1. Check the sealing surface regularly: After running for a period of time, it is necessary to check whether the sealing gaskets of the radially split casing pump and the pump cover are aging or deformed. If there is leakage, replace it in time.

2. Clean up the impurities in the flow channel: After the radially split casing pump delivers the medium containing particles, it is best to rinse the flow channel with water to prevent the adhesion of impurities from causing more serious wear on the inner wall.

3. Do a good job of anti-rust treatment: stop the radially split casing pump for a long time. After cleaning up the residual medium, apply anti-rust oil to the surface, and store the radially split casing pump in a dry and ventilated place to prevent the pump body from rusting.

Customized service:

Our company can provide customized service. You can send us your detailed drawings and purchase requirements to ensure that the product is highly compatible with your needs.

About us:

Dalian Jiachuang Metal Manufacturing Co., Ltd. adopts advanced testing equipment and a complete quality control process. Our radially split casing pump fully complies with industry standards and guarantees the authenticity of test data, which can provide customers with high-quality service guarantee. If you are interested in our company or products, you are welcome to contact us or leave your information. We look forward to communicating and cooperating with you!