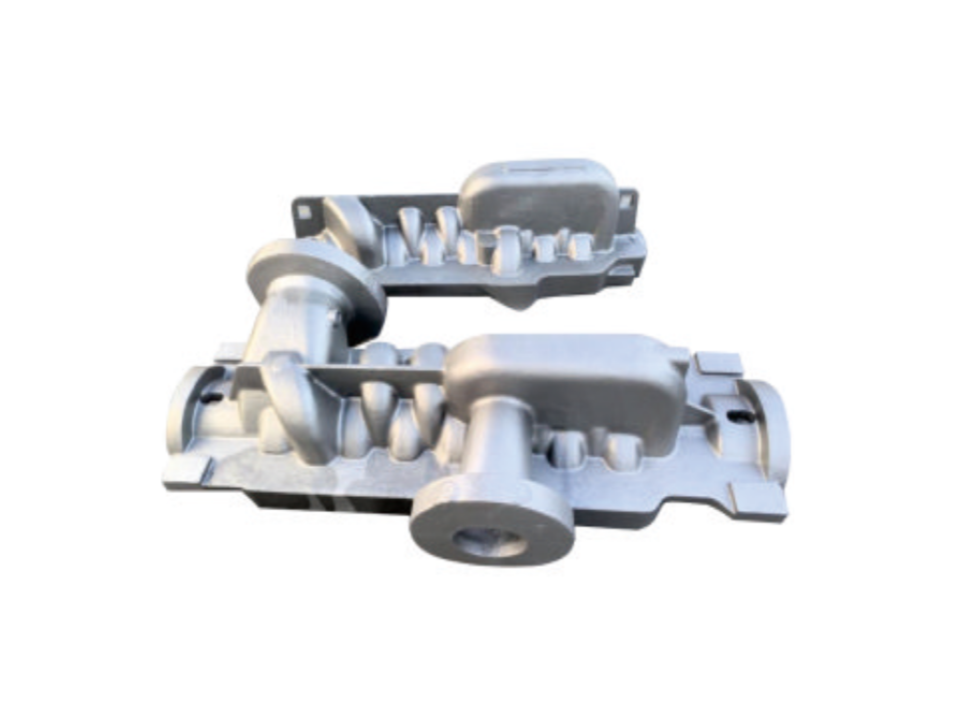

Introduction of multistage pump body:

Multistage pump body is made of high-strength raw materials, including cast steel, austenitic stainless steel and other materials, which are manufactured by precise sand casting process, which has the advantages of high strength, corrosion resistance and high pressure resistance. Multistage pump body can adapt to mainstream multistage pump brands at home and abroad, and the application scenarios of multistage pump body castings are very wide.

Advantages of multistage pump body castings:

1. Our multistage pump body castings are cast with high-strength cast steel and austenitic stainless steel, which are significantly better than ordinary multistage pump body castings in hardness and wear resistance, and can be suitable for working scenarios with particle-containing media.

2. Our multistage pump body castings are simple to maintain and have a long service life, which can reduce the replacement cycle of multistage pump body castings and reduce the cost of maintenance.

3. Our multistage pump castings comply with ISO 9001 quality management system, which is guaranteed to meet industry standards.

Application scenarios of multistage pump castings:

1. Industrial field: multistage pump castings can be applied to acid and alkali solution transfer pumps in the chemical industry and pure water preparation pumps in electronics factories.

2. Mining field: multistage pump castings can be used in underground coal mine drainage pumps and chemical high-pressure water injection pumps.

3. Construction field: multistage pump castings can be applied to building water supply multi-pressure pumps and pipe network booster pumps.

FAQ:

Q1: How long is the warranty period for multistage pump castings?

In the case of non-human damage, the standard warranty period of stainless steel casting pump body is 12 months.

Q2: How to tell when the pump body of the multistage pump needs to be replaced?

If the stainless steel casting pump body has cracks or leaks on the surface, the noise suddenly increases during operation, and the flow rate or head drops too much after the impeller problem is eliminated, it is recommended to replace the stainless steel casting pump body.

Q3: How can I tell if the stainless steel casting pump body is compatible with my multistage pump model?

You can determine by providing a photo of the nameplate of the pump set including the model and parameters, measuring the diameter of the inlet and outlet of the original stainless steel casting pump body and the distance between the mounting holes, or informing the use scenario, etc., and our technicians will help you choose the stainless steel casting pump body.

Customized service:

Our company can provide customized service. You can send us your detailed drawings and purchase requirements to ensure that the product is highly compatible with your needs.

Why choose us:

Dalian Jiachuang Metal Manufacturing Co., Ltd. has a professional technical team and excellent designers. We can ensure that every product meets the customer's procurement standards. We adopt an efficient production model that integrates molding, casting and machining. We have 24-hour after-sales service, which can quickly respond to customer needs no matter when!