12-16/2025

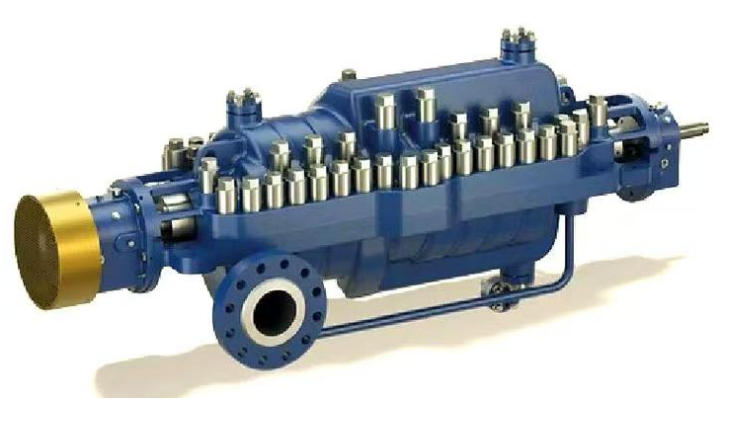

• Process analysis: Our engineers will analyze the structure of the pump casing based on the drawings to determine the parting surface (the location where the mold opens), the gating system (the channel through which the molten metal flows), and the risers (used for feeding and preventing shrinkage cavities).

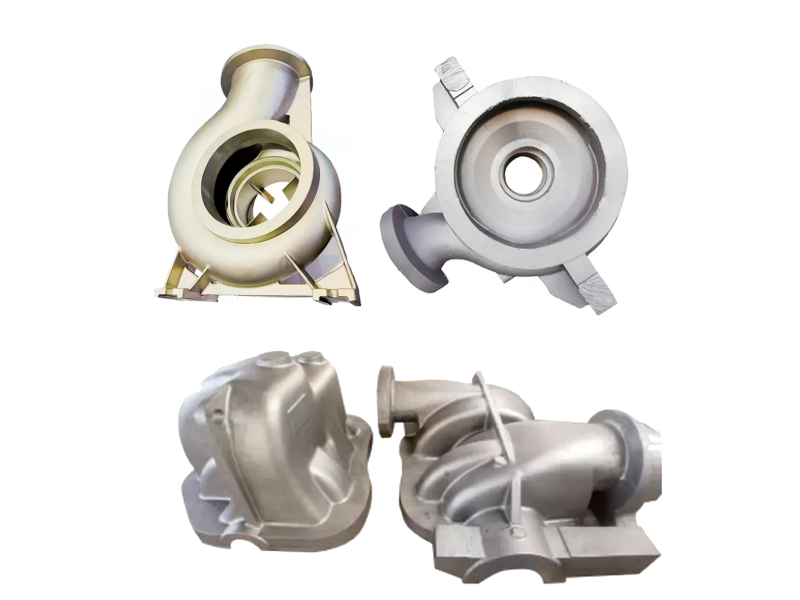

• Pattern making: A "pattern" of the casting pump casing is made according to the design. The material is usually wood (for single pieces or small batches), resin, or metal (aluminum/steel, for large batches).

• Core box making: The inside of the casting pump casing is hollow and has a complex shape (such as the impeller chamber and inlet/outlet flow channels), making direct demolding impossible. Therefore, sand cores must be made. The core box is the mold used to make these sand cores.