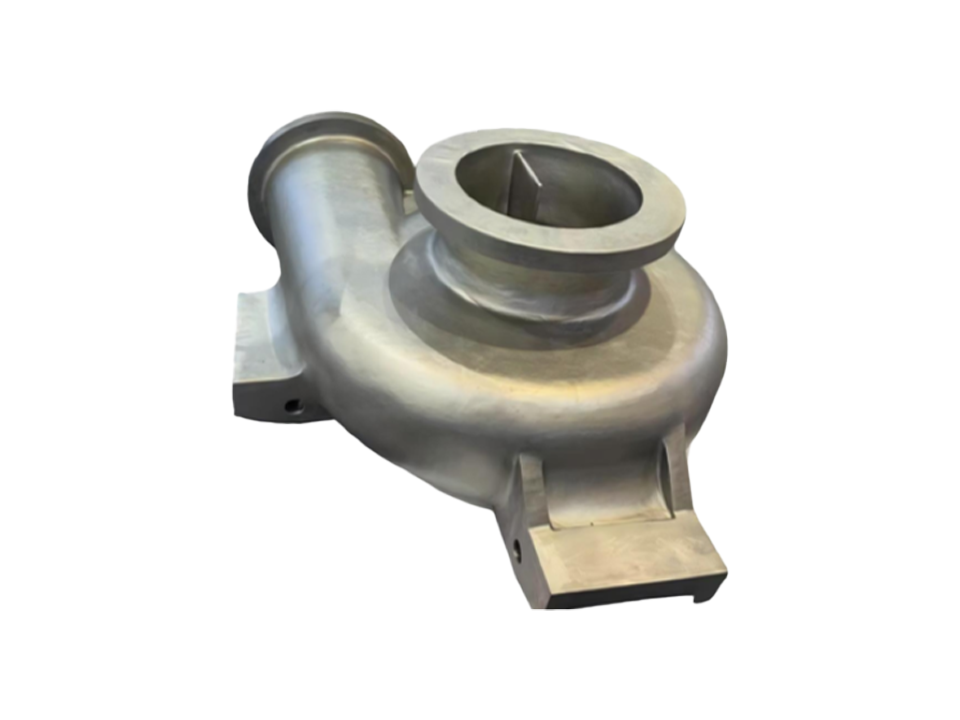

Introduction of centrifugal pump casing:

Centrifugal pump casing is one of the pressure-bearing components in a centrifugal pump. It is made of sand casting. By optimizing the internal flow channel, it can ensure that the medium can smoothly transition from the suction chamber to the pressurized water chamber, and realize the conversion of kinetic energy to pressure energy. It has an important role in the diversion of the medium, the conversion of pressure and the support structure.

Advantages of centrifugal pump casing:

1. The surface of the flow channel of stainless steel pump casing is finely polished, with high conveying efficiency and low energy consumption.

2. Each piece of stainless steel pump casing has passed non-destructive testing and dimensional tolerance testing, and the quality of the product is guaranteed.

3. Stainless steel pump casing is made of duplex stainless steel, which has high strength, corrosion resistance, and is more wear-resistant than ordinary stainless steel.

Selection of stainless steel pump casing:

1. Under normal working conditions, stainless steel pump casing made of ductile iron can be selected, which are usually used in clean water, room temperature and low pressure environments. For corrosion and high temperature and high pressure conditions, stainless steel pump casing made of austenitic stainless steel can be selected, which can withstand corrosive media such as acid and alkali, seawater, etc., and adapt to high temperature and high pressure industrial scenarios.

2. stainless steel pump casing made of ductile iron can be selected for conveying clear water or neutral liquids, and stainless steel pump casing made of two-way stainless steel can be selected for conveying acid-base, salt solutions or media containing particles.

3. Horizontal centrifugal pumps can choose radially divided pump housings, and vertical centrifugal pumps can choose axially divided pump housings.

Scope of use of cast steel centrifugal pump casing:

1. Cast steel centrifugal pump casing is widely used in boiler water supply, cooling system and hydraulic station oil supply equipment in the field of industrial manufacturing.

2. Cast steel centrifugal pump casing is often used in municipal projects in urban water supply and drainage, sewage treatment, and tap water pressurization scenarios.

3. Cast steel centrifugal pump casing can be used in petroleum transportation, chemical reactor feed, and circulating water for power plants in the energy and chemical industry.

4. Cast steel centrifugal pump casing can carry out food-grade media delivery and other work in the field of food and medicine.

Customized service:

Our company can provide customized service. You can send us your detailed drawings and purchase requirements to ensure that the product is highly compatible with your needs.

Why choose us:

1. Our company adopts a production model that integrates molding, casting and machining, with fast delivery cycles.

2. Every product of our company complies with the ISO 9001 quality control system, which can ensure the quality of the product.

3. Our supply capacity can reach 2000 tons/year, and we can provide customized services according to customer drawings.