11-20/2025

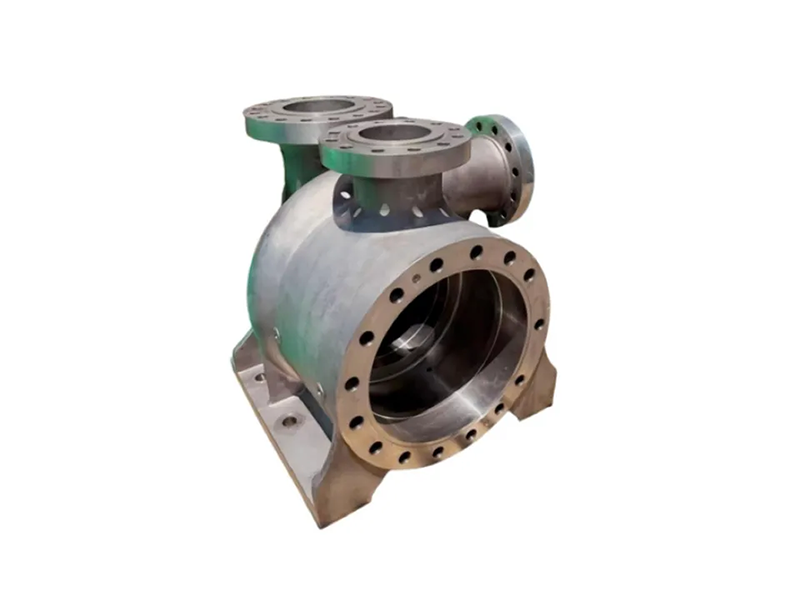

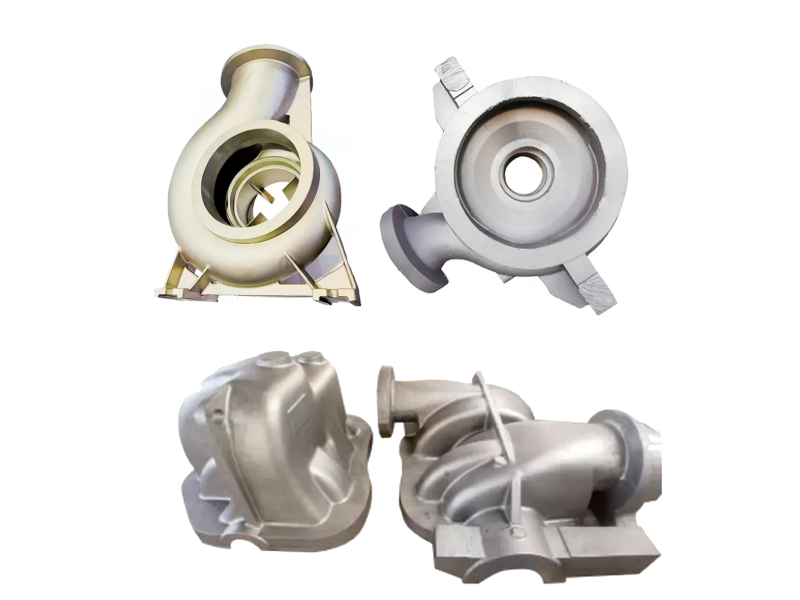

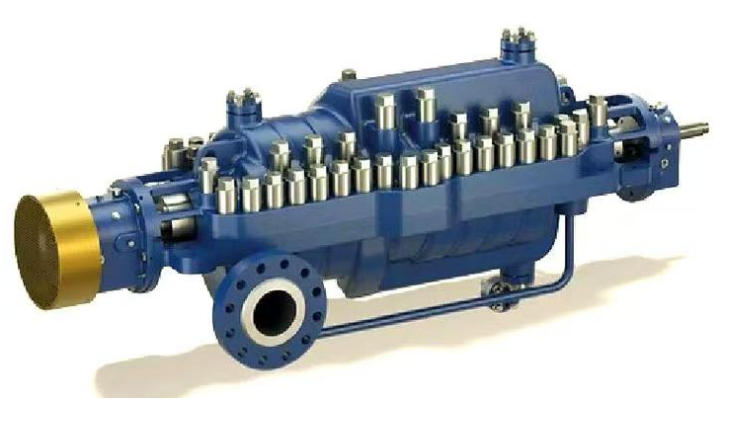

As the core pressure-bearing component of pump systems, the casting quality of pump casings directly determines operational stability, service life, and safety performance. Across industrial applications—from centrifugal pumps for agricultural irrigation to corrosion-resistant pumps in chemical plants, and high-temperature/high-pressure pumps in power systems—these cast casings play an indispensable role. High-quality casings effectively withstand medium pressure and resist corrosion, ensuring smooth fluid flow. Conversely, substandard casings may develop leaks or cracks, potentially causing equipment failures or even safety incidents. Therefore, in-depth research into material selection, process optimization, quality control, and technological innovation for pump casings is crucial for enhancing the overall performance of pump systems.