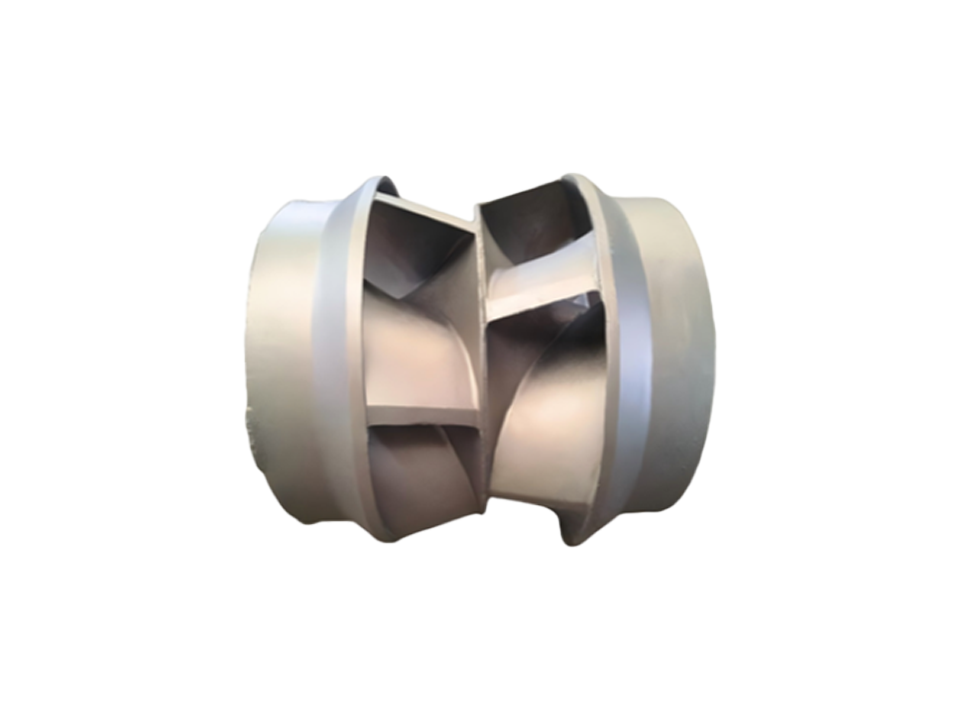

Introduction of double suction impeller:

A double suction impeller made of austenitic stainless steel made of sand casting process. The double suction structure of cast stainless steel impeller can inhale fluid from both sides at the same time. With the streamlined and symmetrical blade design, it can achieve low cavitation and high efficiency operation under high flow conditions. Cast stainless steel impeller is suitable for work scenarios with high requirements for flow and smooth operation.

Advantages of double suction impeller:

1. Both sides of the cast steel double suction impeller can inhale fluid symmetrically, reducing the inlet flow rate, because the cavitation margin of the cast steel double suction impeller is lower than that of the single suction impeller, it can reduce the damage of cavitation to the blade, while improving the operating efficiency of the pump body.

2. The austenitic stainless steel used in cast steel double suction impeller has excellent corrosion resistance. The 316 model can withstand weak acids and alkalis, seawater and other media, and the 304 model is suitable for the transportation of clear water and neutral fluids, which fully meets the anticorrosive needs of many industries.

3. The blades and wheels of cast steel double suction impeller are designed symmetrically. The sand casting process can ensure the uniform distribution of weight on both sides, high dynamic balance accuracy, reduce the radial force on the pump shaft, and extend the overall life of the pump body.

Application of cast steel double suction impeller:

1. Municipal water supply: cast steel double suction impeller is often used in urban waterworks and water supply systems in large residential areas to deliver clean or lightly polluted water.

2. Agricultural irrigation: cast stainless steel impeller can be used in pumping stations in large irrigation areas for long-distance, high-flow farmland irrigation and water transportation.

3. Metallurgical industry: cast stainless steel impeller can transport fluids such as cooling water and turbid circulating water in the smelting process.

4. Sewage treatment: cast stainless steel impeller is often used in reflux pumps and lifting pumps in sewage treatment plants to transport treated fresh water or mild sludge water.

About us:

Dalian Jiachuang Metal Manufacturing Co., Ltd. covers an area of 30,000 square meters. The main business includes ferrous metal casting, mold manufacturing, machining, etc. We have a professional technical team and advanced processing equipment. In order to reassure customers, we will ensure that every product meets customer standards and industry standards. If you have any questions, you can contact us at any time, we look forward to your message!

Customized service:

Our company can provide customized service. You can send us your detailed drawings and purchase requirements to ensure that the product is highly compatible with your needs.

FAQ:

Q1: Why is cast stainless steel impeller more suitable for high-flow scenarios than single-suction impellers?

Cast stainless steel impeller can absorb water from both sides at the same time, the inlet cross-sectional area is larger, and the flow rate can be transported at the same speed, and the symmetrical structure balances the radial force, which can reduce the wear of the pump shaft and is suitable for long-term high-flow operation.

Q2: How to tell if cast stainless steel impeller needs to be cleaned?

If the flow rate of the cast stainless steel impeller pump body drops by more than 5%, the outlet pressure decreases, or the operating noise increases, it may be that there is residual scale or impurities on the surface of the impeller. It is recommended to stop for inspection and cleaning.