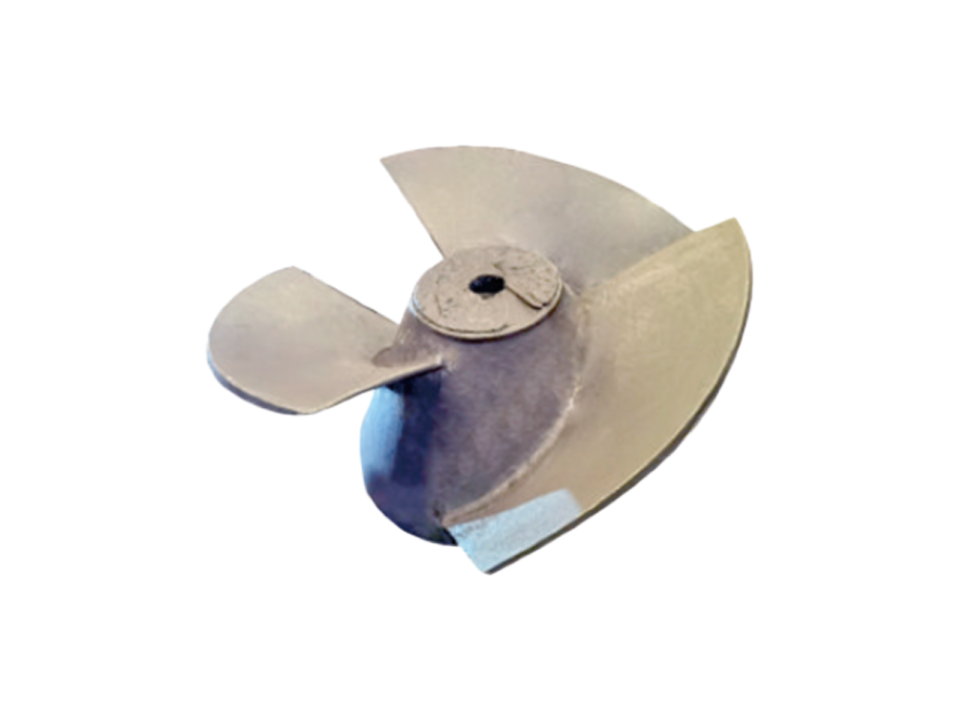

Introduction of axial pump impeller:

The axial pump impeller made of austenitic stainless steel adopts a sand casting process. Unlike centrifugal and double-suction impellers, the axial thrust design of axial pump impellers is powered by the axial thrust generated by the rotation of the blades. The fluid enters and exits along the axis of the impeller without converting energy through centrifugal force. Axial flow pump impeller is suitable for operation in low-head, ultra-high-flow scenarios.

Features of axial flow pump impeller:

1. The axial flow pump impeller cooperates with the principle of axial thrust and has a high single-stage flow rate. Under the working conditions of 5-30 meters head, the efficiency of the centrifugal impeller is obvious compared to that of the centrifugal impeller.

2. The axial flow pump impeller's axial flow channel design can reduce the loss of fluid impact. At the same flow rate, the motor power is significantly reduced compared to the centrifugal impeller of the same specification, and long-term operation can save costs.

Application of axial flow pump impeller:

1. Water conservancy engineering: axial flow pump impeller can be used for flood control and drainage of large pumping stations and river dredging to achieve high-flow water transportation.

2. Municipal drainage: axial flow impeller can be used for emergency drainage of urban heavy rains and tailwater discharge from sewage treatment plants, which can cope with short-term large flow requirements.

3. Shipbuilding industry: axial flow impeller can be used for propulsion and bilge drainage of large ships to adapt to underwater high humidity environments.

About us:

Dalian Jiachuang Metal Manufacturing Co., Ltd. has a modern production site, experienced staff and high work efficiency. The company has honors such as PQR and WPQ welding qualification certificates, advanced processing equipment and professional testing equipment, and can be responsible for every product produced. If you need to purchase metal castings, we will be your best choice!

Customized service:

Our company can provide customized service. You can send us your detailed drawings and purchase requirements to ensure that the product is highly compatible with your needs.

FAQ:

Q1: What is the core difference between axial flow impellers and centrifugal impellers?How to choose?

The core difference is in the characteristics of flow and head. Axial flow impellers are suitable for working environments with large flow and low head, while centrifugal impellers are suitable for working environments with small flow and high head. If your work scenario requires a large amount of fluid to be transported but the head requirements are not high, you can give priority to axial flow impeller.

Q2: The blades of the axial flow impeller vibrate slightly when it is running. Does it need to be stopped for inspection?

You can first check the blade for debris attachment. If it is still vibrating after cleaning, you need to measure the vibration value. If ≤0.15mm/s is the normal situation, it may be a dynamic balance deviation if it exceeds it. You need to contact us for recalibration to prevent long-term vibration from causing structural fatigue.