10-31/2025

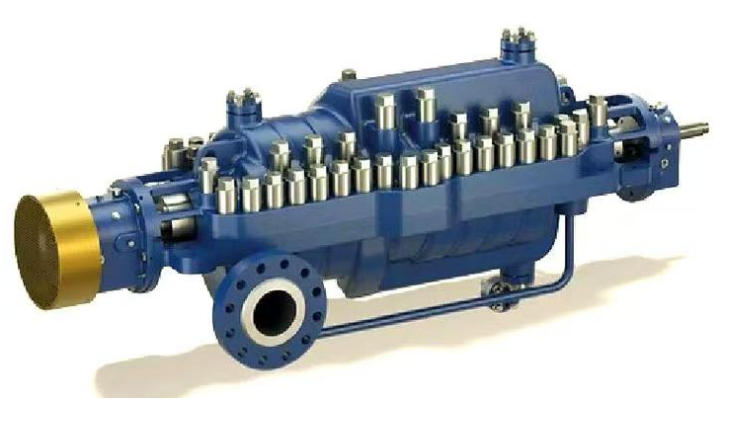

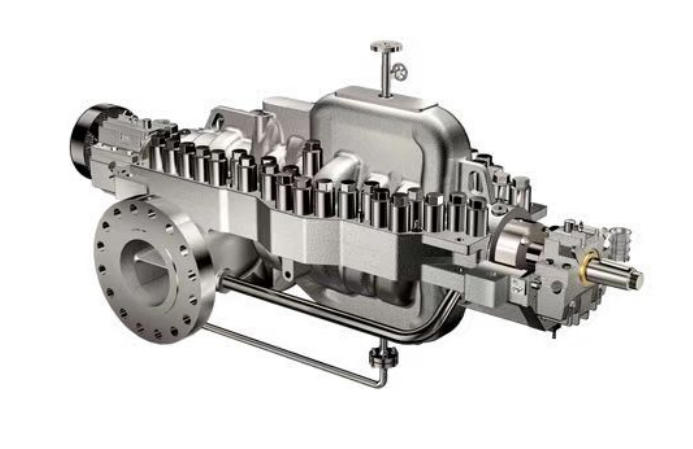

As a core flow component in fluid machinery, guide vanes are extensively used in critical equipment such as water turbines, pumps, and compressors. Their performance directly impacts the efficiency, stability, and service life of the entire system. These components must withstand complex hydrodynamic loads, material corrosion, and temperature fluctuations, requiring stringent specifications for material properties, structural precision, and surface quality. Casting serves as the primary manufacturing method for guide vanes, involving multiple critical processes including material selection, mold design, melting and casting, heat treatment, and quality inspection. The quality of the casting process directly determines the final product's performance. This article will delve into the technical aspects, process optimization, and quality control of cast guide vanes.